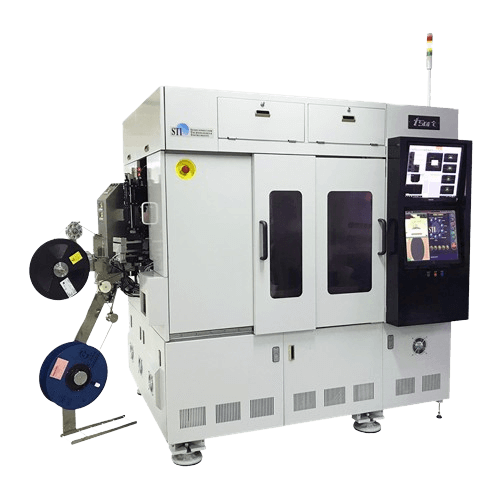

STI tSort

High Speed Die Sorting

tSort is a cost effective solution developed for high speed die sorting into tape and reel. Process knowledge from our widely acclaimed range of taping machines and vision engines was incorporated into its design – distinguishing it in a class of its own.

Using STI’s proprietary iVISION technology, tSort provides a state of the art vision algorithm for inspecting wafer level chip scale packages with unsurpassed accuracy and reliability. Aided with an intelligent vision-guided pick and place transfer, it ensures only devices that meet stipulated quality are placed into the output reels, ready for the next process step.

tSort utilized cutting edge technologies in robotic motion control and as such comes packaged with a user friendly interface, providing a truly robust solution for today’s demanding production environment.

iSORT Express utilizes cutting edge technologies in robotic motion control and as such comes packaged with a user friendly interface, providing a truly robust solution for today’s demanding production environment.

Features

- Inspects Bump and Pad WLCSP Devices

- True Measurement Method

- 2D & 3D Wafer Bump Metrology Provide

- Coplanarity Measurement

- Bump Damage Detection Metrology

- Edge and Corner-chipping Inspection

- Active Die Surface Inspection

- Carbon Coated Die Inspection

- 2D Matrix and OCR Ready

- Post Seal Inspection

- Seal Line Quality Check

- Automated Accuracy Check

- Colour Inspection Solution

- Automated Dual Taper

- Skeleton Wafer Verification

- Side Wall Micro Crack Inspection

- Wafer Reconstruction

- Auto E-Pin Verification

- IR Inspection Capability for Post Seal

- Back Side & Side Wall