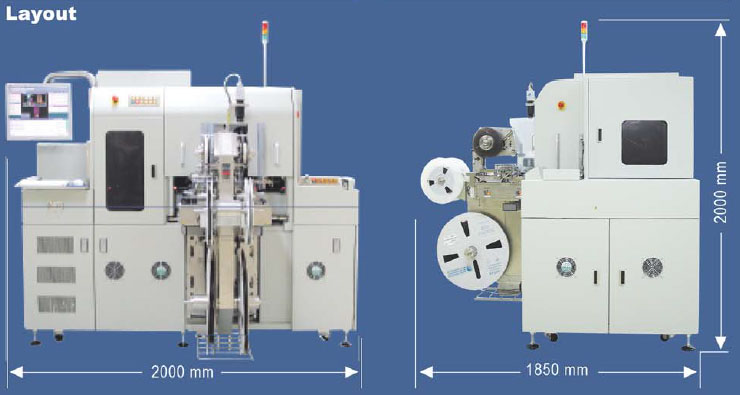

STI - Hexa Evo / Evo+

Integrated Tray-based Scan Pack

2D/3D High Speed Scanner for Large Form Factor Packages

The Hexa Evo is the latest addition to the highly successful Integra Hexa family. It provides the most comprehensive quality assurance solution for detection of backend process induced defects for all ball array, peripheral leaded / leadless and large form factor packages.

The highly modular design concept allows flexibility for various options like – Dual taper, auxiliary tray input, top and bottom surface inspection, side surface inspection etc. Simple and repeatable conversions also make the Hexa Evo perfectly suited for customers with high mix, small lot size production environment.

STI’s proprietary vision solution encompasses pioneering technology in areas such as optics design, lighting control, and software algorithm. Coupled with advanced automation features, the Hexa Evo offers a diverse menu of inspection and output options configurable to match all package requirements.

Features

- Suitable for all EOL packages

- Powerful auto teach algorithm

- Sub pixel defect detection and measurement

- Automated accuracy check

- Side surface inspection

- True ball height

- 3D for ultra small balls of 20µm ball height

- Flexible pad inspection

- OCR and 2D Matrix capable

- Micro crack detection

- Lead burr inspection

- Exposed wire inspection

- Image sensor inspection

- Resin bleed and mold flash inspection

- In-Pocket inspection

Tray Scanner

Large FOV

The Hexa Evo is equipped with a wide-angle capability of acquiring very large field of FOV) Images at high and uniform resolution. With this feature, multiple device s can be captured with per picture take, resulting in a quantum leap in UPH. worthy is the enhanced image details without compromising the throughput.

Dual Taper Advantage

The dual taper is designed to complement high taping speeds of 18k UPH. It allows uninterrupted machine operation during material changeover resulting in drastically increased productivity. Post Seal inspection completes the extensive quality assurance solution provided in the Hexa Evo.

True 3D On-The Fly (OTF) Inspection Metrology

Cutting edge technology in our patented 3D OTF module provides TRUE 3D measurements for all devices. Using advanced laser and camera metrology techniques, even “ultra small” ball coplanarity and device warpage can be measured consistently with precision.